There are many kinds of amusement equipment and various kinds of material of equipment and the quality of the products depends largely on the quality of the raw materials.

Because of its high strength, light weight, strong corrosion resistance, good toughness, and other characteristics, fiberglass is widely used in amusement facilities, especially water playground equipment. Meanwhile, more than half of the water park equipment produced by Cowboy Group uses fiberglass as the production material to manufacture. Which advantages does fiberglass have and why is the fiberglass so popular?

Fiberglass is a kind of fiber reinforced plastic and consists of reinforcing material(fiberglass or its products)and resin matrix. In professional terms, the full name of the fiberglass is fiber reinforced composite.

Outstanding Advantages and Wide Range of Application

Material Characteristics: High Strength, Light Weight, Corrosion Resistance, Flame Retardant, Strong Weather Resistance, Ageing Resistance, High-Temperature Resistance, etc.

Strong Plasticity: Fiberglass has a special material structure and simple process that can be formed at a time and it also has strong plasticity which can be according to the needs of each customer to flexibly design each amusement equipment.

Color Dominance: Fiberglass is generally used to attach color gelcoat or spray car paint, and its color is bright and does not fade. Besides, fiberglass can also be used for a wide range of products.

Strong Corrosion Resistance and Longer Service Life

The amusement facilities of water playgrounds are in a severe environment of humidity, high temperature, and exposure for a long time, therefore using fiberglass to be the raw material can effectively decrease the damage caused by corrosion and prolong the service life of the amusement facilities. The weight of the same volume of fiberglass is only 1/4 of the weight of steel, which means that fiberglass can not only be easy to carry and install but also decrease transportation costs. Therefore, fiberglass is very popular and favored by water playground investors.In the water park, fiberglass is used in the production materials of various water slides, slide rails, water houses, water play equipment and other structures.

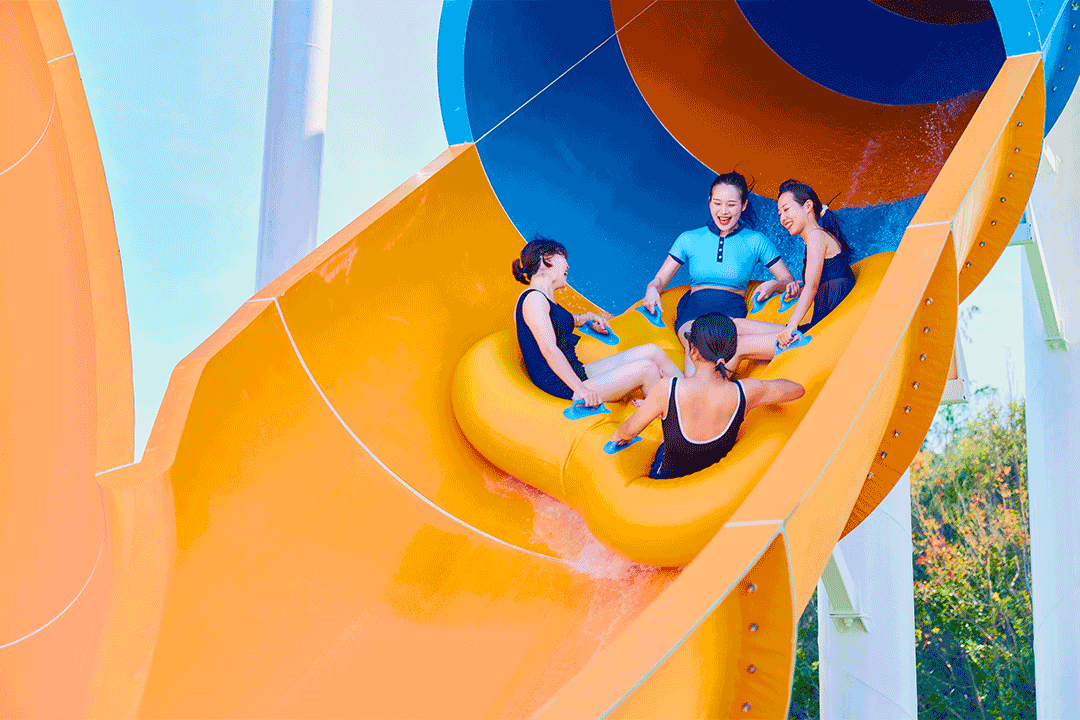

Fiberglass Slide

The water slide is one of the core projects in the water park, and the water slide with various special shapes and exciting experiences attracts many tourists to play. Because the design of fiberglass slide has strong flexibility, it can be based on the theme of the park to conduct a custom production. However, the strong corrosion resistance also makes the fiberglass slide more durable in humid and high-temperature environment compared to other material slides.

Water House

The main material of the frame of the water house is mainly divided into carbon steel and fiberglass. Compared with carbon steel, the material weight of fiberglass is lighter, and the surface adhesion layer is gelcoat, which makes the color and pattern richer, and the impact of corrosion resistance on the water quality of the park is less. Through careful combination and collocation, the water house becomes an interactive product that meets the tourists’ splashing adventure and play experience and it is also a comprehensive water amusement equipment integrating all kinds of water play toys,roof pour bucket water play equipment, water slides, theme landscapes, etc.

Water Play Equipment

After surface treatment, the fiberglass water play equipment formed once has a bright and smooth appearance and it provides tourists with a safer play experience. As the auxiliary equipment of the water park, the water play equipment is the landscape embellishment and various cute and cartoon images water play equipment can not only spray water but also participate in the interactive amusement, adding some lively and funny atmosphere.

Other Amusement Equipment

Except in water parks,outdoor playgrounds and indoor playgrounds often use fiberglass as the raw material to produce the products : Different kinds of eye-catching cartoon images in children’s parks, whale in the pool, hedgehog spray equipment, lion’s head for a lion dance slides made of fiberglass……

Different Uses and Different Manufacturing Techniques

The composite Material Molding Process is the basis and condition for the development of the composite material industry. As the molding process is becoming more and more perfect, the new molding process is constantly occurring. There are some simple introductions for the fiberglass product molding process in the amusement industry, for instance, Hand Lay-up Molding, RTM Molding, VIP Molding, Pultrusion Moulding and SCM Molding.

At present, the special shape fiberglass products that were seen in the outdoor playground usually use the hand lay-up molding process, and this process is not limited by the categories and shapes, especially adapting to the small quantities of custom products. However, the quality of hand lay-up molding depends on the operator’s proficiency, the quality of the product is unstable and this process is not suitable for mass production.

RTM(Resin Transfer Molding Technology)is a closed mold-forming process. Compared to the hand lay-up molding process, the product’s performance of RTM Molding has effectively improved: The fiber content of the product is improved and the product is light, high strength, stable quality, uniform thickness and no gap. The surface of the product adopts the air-dry gelcoat which has better wear resistance and does not fade when it is used in the water for a long time.

The Vacuum Infusion Process ,VIP for short, makes use of the pressure produced by vacuum to make the product mold and the product has a good surface flatness, uniform thickness, high fiber content, low porosity, premium product performance, and high interlayer strength, which can greatly improve the fatigue expansion performance of the product. Furthermore, the water slides of the water playground often apply the VIP Molding Process, but the one-time consumables required by the VIP Process are higher, and the technical requirements for operators are higher, which greatly increases the cost.

The Pultrusion Moulding Process can realize the full automation of the production process and has higher production efficiency. Meanwhile, the product’s fiber content arrives at 80%, so it has a strong strength, especially longitudinal strength. However, this Pultrusion Moulding Process also has an obvious disadvantage. Since the transverse strength is low, the shape of the product is single and simple. At the same time, this technology can only produce linear material.

The Sheet Molding Compound is called SCM for short.The SCM Molding is often used to make fasteners, connectors, and trim pieces. Compared with metal connectors, SCM has strong strength, corrosion resistance, low cost, and other advantages. Furthermore, the SCM Molding Process is the most efficient process in the production of composite material and has high precision, good repeatability, smooth surface, and no secondary modification. Moreover, the SCM mould is difficult and complex to produce and requires vast investment, which it suitable for manufacturing small and medium size products.

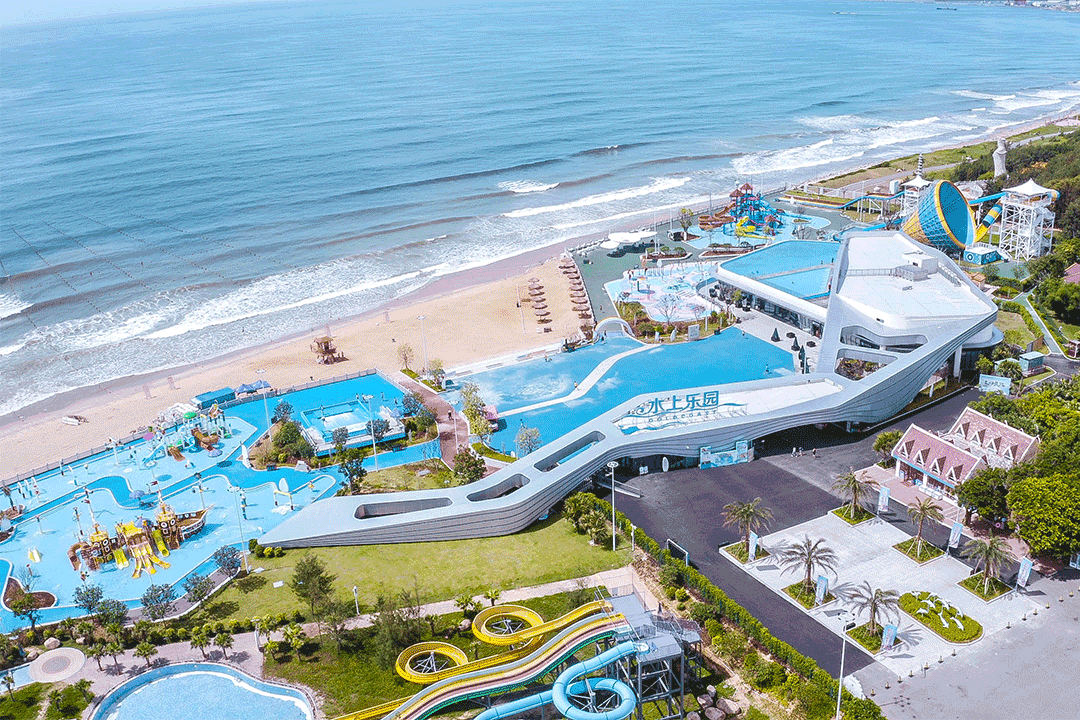

The project of Golden Coast Water Playground in Shantou City, Guangdong Province, China creates a precedent for using seawater recycling to build a marine water park but if the products are immersed in the seawater for a long time, these products will exist the danger of rust and corrosion. Therefore, Cowboy Group exploits the SMC Molding Process and RTM Molding Process and all fasteners change for fiberglass material, which can greatly promote the corrosion resistance of equipment and fasteners and ensure that they will not degenerate and metamorphism for 50 years.

The pirate ship water house of Morocco M’nar Park Water Park adopts fiberglass pipe by Pultrusion Moulding Process instead of the common steel pipe and this belongs to the first application in the water park field. Except for some part fasteners that use 304 stainless steel, the whole pirate ship is made of high-performance composite material fiberglass, which never rusts.